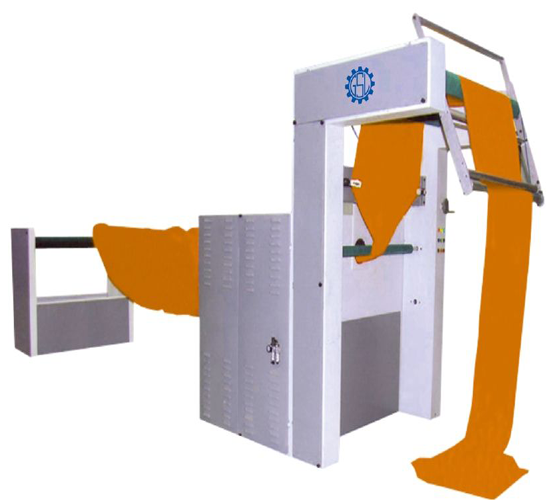

It is designed to reserve the knitted fabrics in tube from from before and after dyeing/raising. Operation of this machine is very simple. even an untrained worker can operate. A roll weighing 20 Kg. of knitted fabric can be reversed in 50 seconds only Process starts by foot stepping the paddle, the blower starts. Manually put the fabric on outer surface of the pipe, the roll starts opening and the fabric collects on the pipe. Five to six rolls collects on the pipe, and then by other foot stepping the paddle. and inserting the fabric end manually on the mouth of the pipe, the flow of air sucks the entire fabric in and reverse it.

Special Features:

Versatile Reversing Functionality: Our Reversing Machine is designed to perform a variety of reversing operations on textile materials, including fabrics, garments, and technical textiles. It can reverse the direction of material flow, allowing for precise control and manipulation during finishing processes.

Precise Control and Adjustment: Equipped with advanced control systems, our machine offers precise adjustment of reversing parameters such as speed, tension, and reversing angle. Operators can fine-tune these settings to achieve the desired finish and quality for different types of textile materials.

Efficient Material Handling: The mechanical design of our Reversing Machine ensures smooth and efficient handling of textile materials, minimizing material distortion and damage during the reversing process. Fabric rolls, garments, or other textile products can be easily loaded onto the machine for processing.

Customizable Reversing Patterns: Operators have the flexibility to create customizable reversing patterns to suit specific finishing requirements. Whether it's crease removal, wrinkle reduction, or fabric relaxation, our machine allows for precise control over reversing movements to achieve optimal results.

Uniform Treatment: With its advanced design and precise control systems, our Reversing Machine ensures uniform treatment of textile materials, resulting in consistent quality across the entire product. This uniformity enhances the overall appearance and performance of the finished textiles.

Robust Construction: Built with high-quality materials and precision engineering, our machine is designed for durability and long-term reliability. Its robust construction ensures stable operation even under demanding production conditions, minimizing maintenance requirements and downtime.

Safety Features: Safety is paramount in our machine design. The Reversing Machine is equipped with safety interlocks, emergency stop buttons, and protective guards to ensure safe operation for operators and prevent accidents.

Why Choose GS Textile India Pvt. Ltd.'s Reversing Machine?

Expertise and Experience: With over six decades of experience in textile machinery manufacturing, we have the expertise to deliver cutting-edge solutions tailored to the needs of the textile industry.

Quality and Reliability: Our Reversing Machine is built to the highest standards of quality and reliability, ensuring consistent performance and long-term durability.

Customization and Flexibility: We understand that every customer has unique requirements. That's why our machine offers customizable settings and flexible operation to meet the specific needs of different textile finishing applications.

Technical Support and Service: Our dedicated team provides comprehensive technical support and service to ensure smooth installation, operation, and maintenance of our machines, maximizing uptime and productivity.